Indoor Farming Solutions

HOME Indoor Farming SolutionsWith the legalization of Cannabis, EASTechnology is at the front foot to help Licensed Producers (LPs) designing their production facilities. Indoor production requires a very controlled climate in terms of air flow distribution, temperature, CO2 and relative humidity to achieve a high production. Using our Computational Fluid Dynamics (CFD) modeling capabilities, we have helped LPs finalizing the design of their facilities before proceeding with construction. Thus, we can detect any issue with a proposed design and offer better alternatives before it is too late when the construction has started, and correction cannot be done or can be very costly to achieve. We have used Computational Fluid Dynamics (CFD) models to help LPs achieving the following:

- Facility layout design and Analysis : An efficient design of growing facility can play a major role in high yield, costs and energy savings. Using CFD, we can assess the following:

- Air flow Velocity distribution inside the room

- Air temperature distribution around the canopy and height of the stratification layer.

- Heat production by the lights

- Relative humidity inside the room

- CO2 levels produced by the plants

- Detect any hot/cold spots that can affect negatively the plant growth.

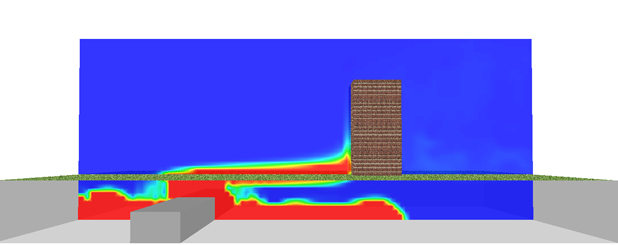

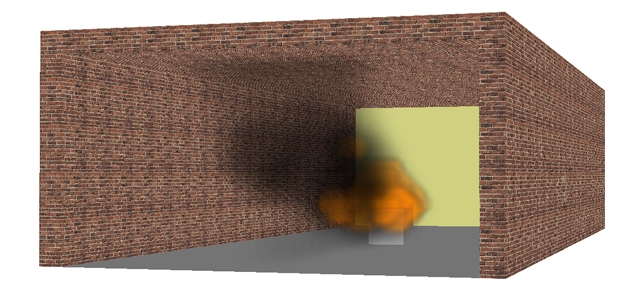

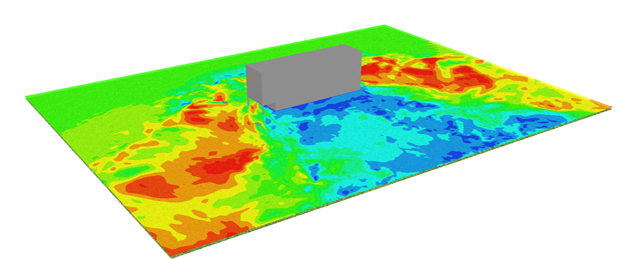

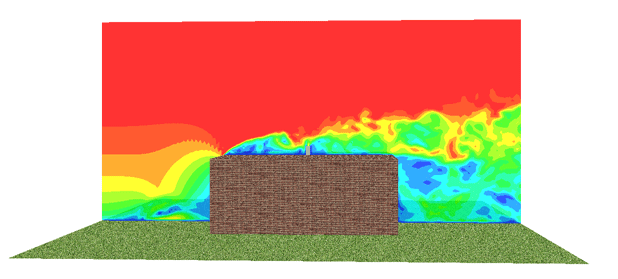

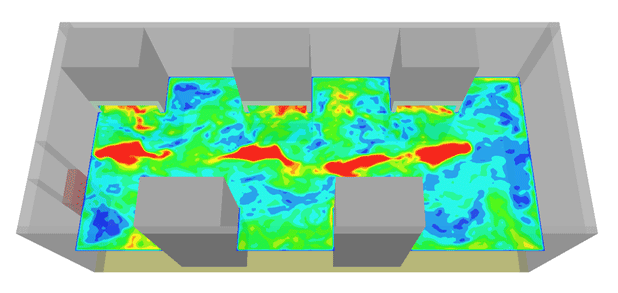

In the figures below, CFD modeling was performed to analysis the climate inside a multi layers flowering room (Fig1a). Figure 1b shows the air distribution across the plant canopy. The cold jet air emanating from the top supply diffuser impacts the first rows of plants and moves downward towards the floor creating a sort of air curtains in front of the first rows, particularly at the highest layers. The cool air moves at the bottom of the floor towards the return grilles located near the floor at the opposite wall. This air movement has induced a non uniform vertical distribution of the temperature (Fig1c) where the two bottom layers are cool enough while the top two layers remain relatively hot. Consequently, this hot air has noticeably reduced the relative humidity at the higher layers (Fig1d). In conclusion, this proposed design will have a negative impact on the plant growth and the estimated yield.

- Facility heat load Analysis: Depending on the facility location, we can assess the following:

- Cooling and Heat load (tons) required for a given design

- Summer and winter conditions

- Design layout mitigation